Scandiff 2 DECOSYSTEM

Vision system software Scandiff | Comparison between PDF file and scanned image of printed product

Vision System Software Scandiff product range

The vision system software Scandiff product line includes three main models: Scandiff2, Scandiff2 PRO and Scandiff CD.

This offline system is dedicated to compare PDF file with the real printing on the product and ensure that there is no mistake on the printing line.

SPECTRO-M

PDF comparison for printed tubes

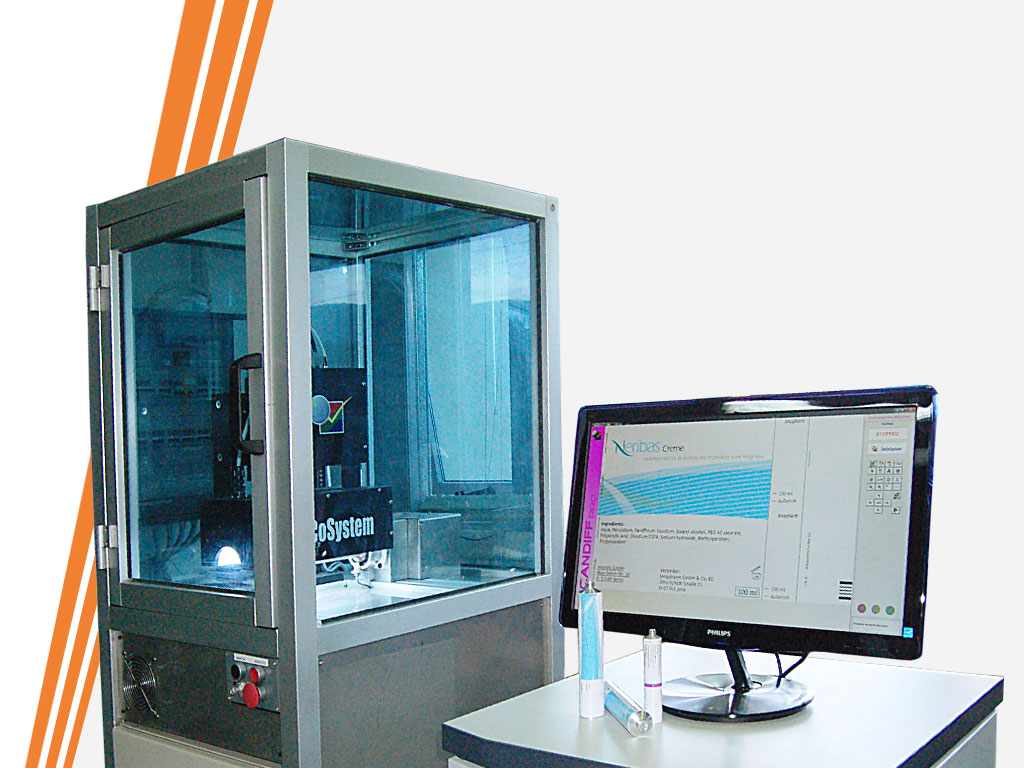

Scandiff2 PRO is an offline system dedicated to comparing printed tubes and digital PDF files. Equipped with a high-resolution line-scanning camera, Vision System Software Scandiff2 PRO can capture images of cylindrical objects such as pipes or sticks. The new version can also be equipped with a CIS sensor, allowing the first print result to be compared with the PDF file provided by the customer.

SCANDIFF 2 PRO

SCANDIFF 2

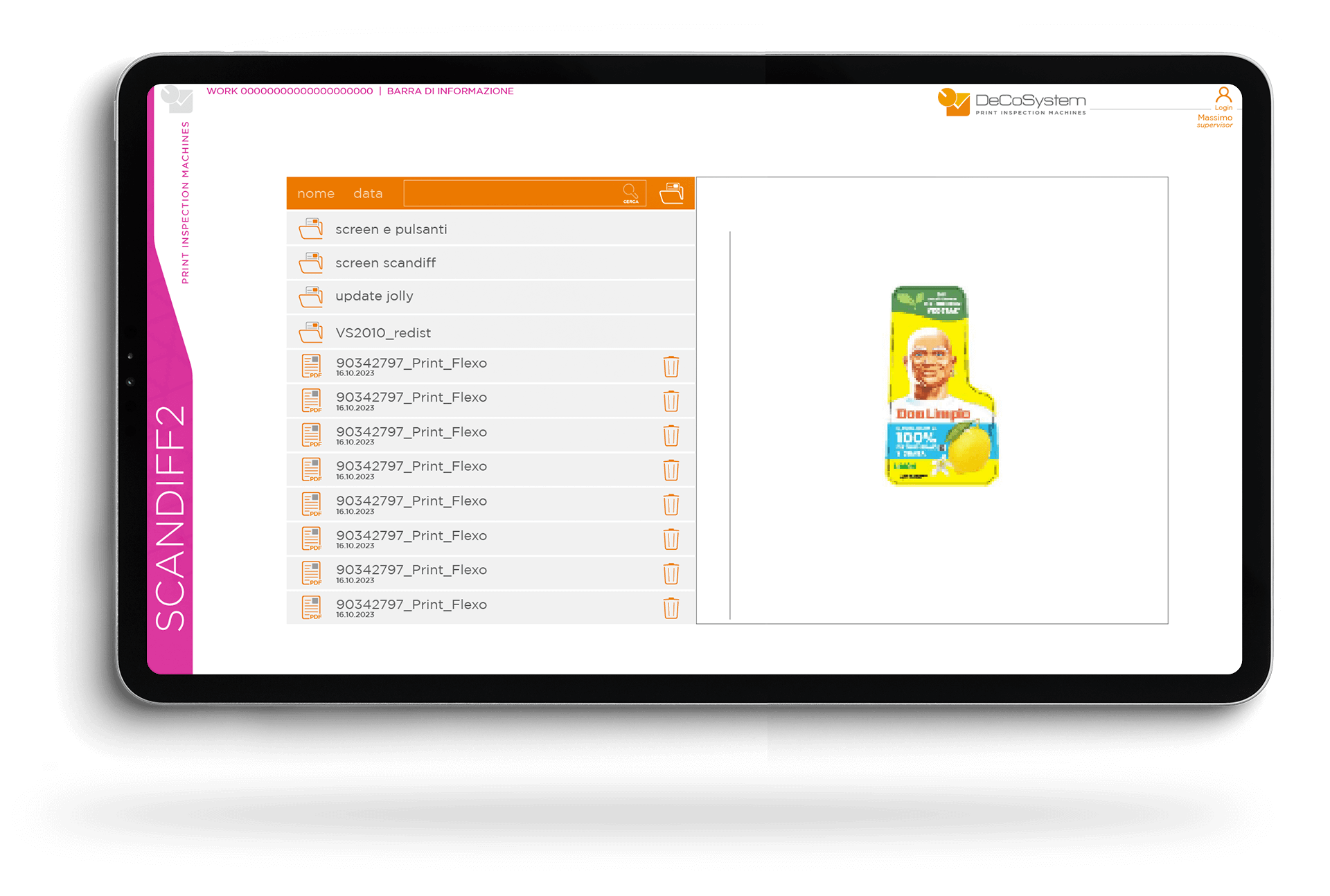

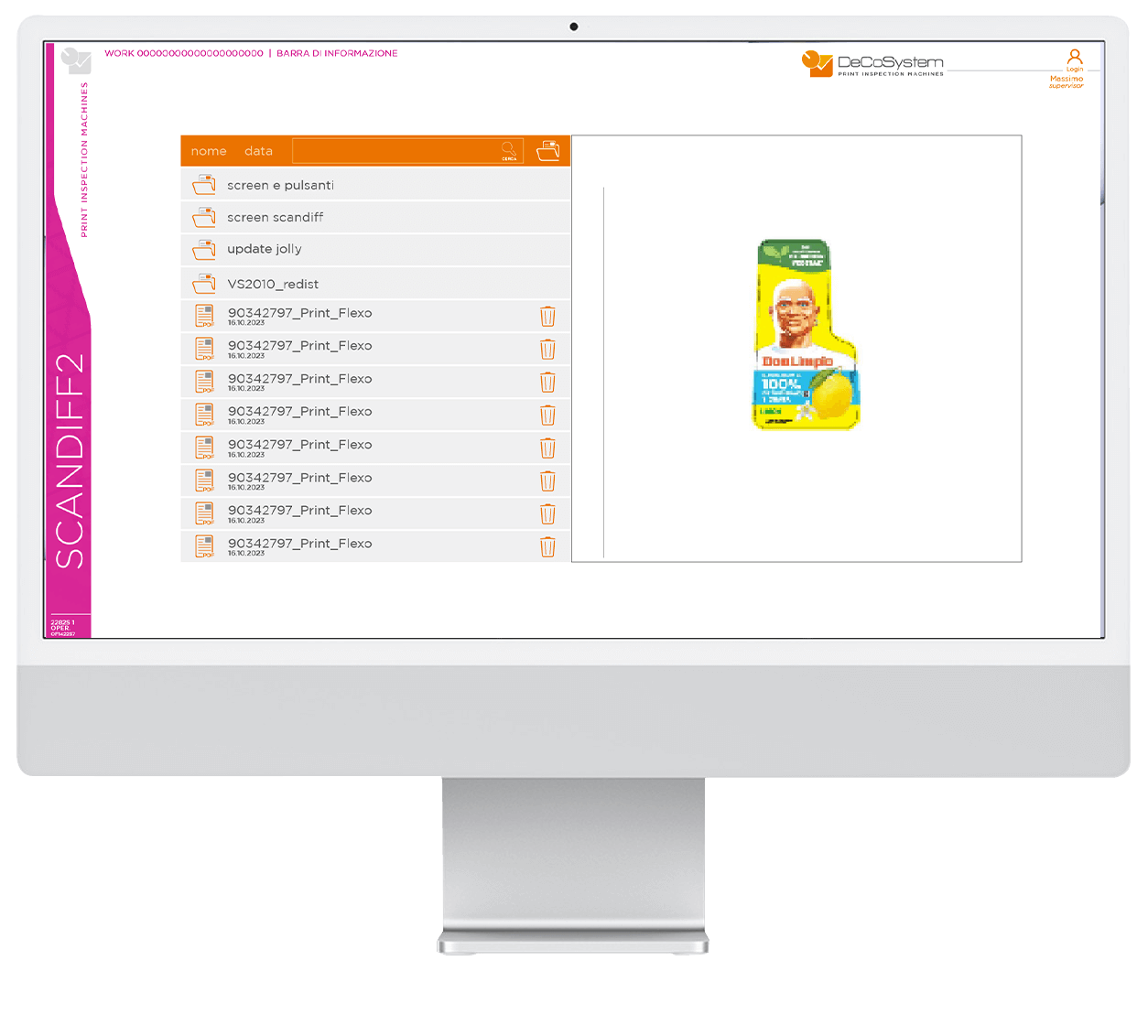

SCANDIFF2

Versatile inspection for various applications

Scandiff2 is an offline digital media comparison system. It handles all common digital image file formats and can acquire image data from dedicated acquisition devices. It is mainly used in the different stages of pre-press document processing, allowing the customer’s reference PDF files to be compared with the documents resulting from pre-press processing and the first printed samples during machine setup.

Print Control on CDs and DVDs

Vision system software Scandiff CD is a new version of the Scandiff system dedicated to the control of CD and DVD printing. The system is particularly suitable for reprinting CDs/DVDs belonging to the same set, allowing you to check whether the new print matches a previously printed sample. Color variations (deltaE) from the reference sample can be controlled, ensuring uniform print quality.

SPECTRO-M

SCANDIFF 2 CD

SCANDIFF 2

Intuitive interface

Scandiff’s vision system software has an intuitive user interface that makes the entire inspection process quick and easy. Operators can set up and start new jobs in minutes, reducing downtime and increasing productivity.

Reducing waste and thus reducing costs

The use of Scandiff systems contributes significantly to reducing production waste, optimizing processes and reducing operating costs. This not only improves production efficiency, but also increases the overall profitability of the company.

Defect detection and classification

Scandiff systems are designed to accurately detect and classify defects. Whether it is printing errors or surface defects, advanced software ensures that any problems are identified and recorded, enabling timely action to correct them.

Easy to use

Scandiff vision system software is designed to be extremely easy to use, requiring minimal training for operators. The intuitive interface and automated features enable users to effectively manage the inspection process, ensuring high-quality results without complications.

THE ADVANTAGES OF THE SCANDIFF 2 VISION SYSTEM SOFTWARE

There are many benefits to using Scandiff systems, including significant improvement in product quality and increased productivity. The ability to compare printed samples with reference PDF files ensures that every detail is perfect, reducing printing errors and optimizing production processes. This results in reduced waste and increased business profitability.

Reducing waste and thus costs

High accuracy and better efficiency

Ease of use

OUR VISION SYSTEM SOFTWARE FOR PRECISION SCANNING

Scandiff 2

Scandiff’s vision system software is at the heart of our inspection technology, combining an intuitive interface with powerful defect detection algorithms. Designed to be easy to use, it allows new jobs to be set up in minutes and offers a wide range of features, including full reporting and automatic storage of all production process data. This ensures that every detail is monitored and optimized, ensuring excellent print quality at all times.

ASSISTANCE

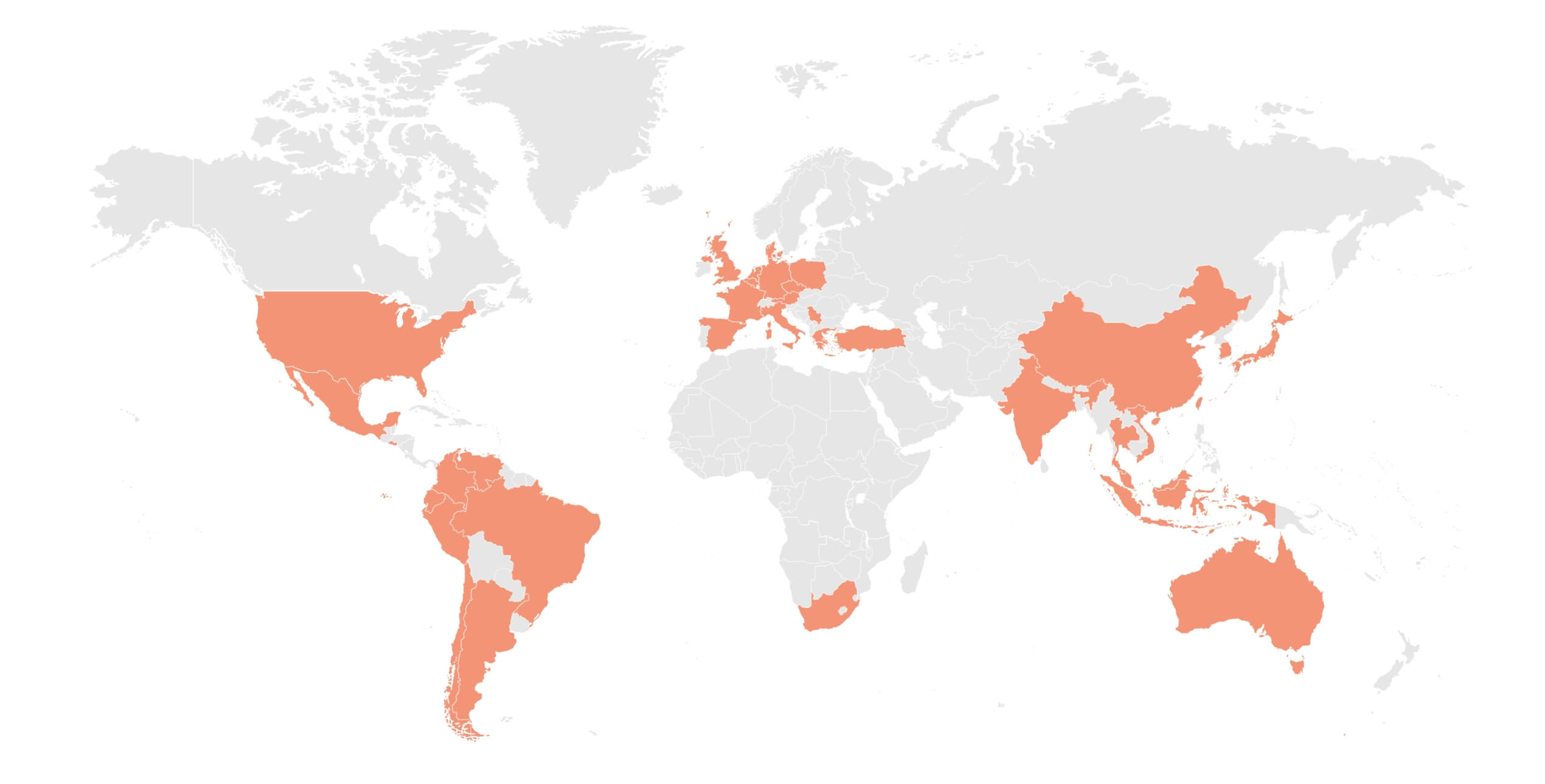

DeCoSystem provides excellent customer service with fast response times and effective solutions. We provide turnkey equipment, great flexibility and software customization, backed by proven experience in the field

+39 055 4564748 | info@decosystem.com