Printing inspection for packaging container MULTIPLUS

Unique offline module for quality control on cosmetic plastic bottles or perfume glass containers.

Print inspection module for packaging container MULTIPLUS 2 types according to the type of containers : PLASTIC or GLASS.

MultiPlus print inspection module for packaging container: Versatile Loading and Unloading System

The MultiPlus platform is a packaging inspection machine designed to accommodate two types of loading and unloading systems, offering flexibility for controlling both blow-molded plastic bottles and glass bottles or jars.

Plastic Bottle Handling When controlling blow-molded plastic bottles, they travel in a horizontal (lay-down) position on the feeding conveyor. A precision pick-and-place mechanism grips each bottle in its horizontal orientation and rotates it 90 degrees, positioning the neck upright (chuck and countersinking). After inspection by the integrated camera system, the same pick-and-place mechanism carefully unloads the bottle onto the outfeed conveyor in horizontal position.

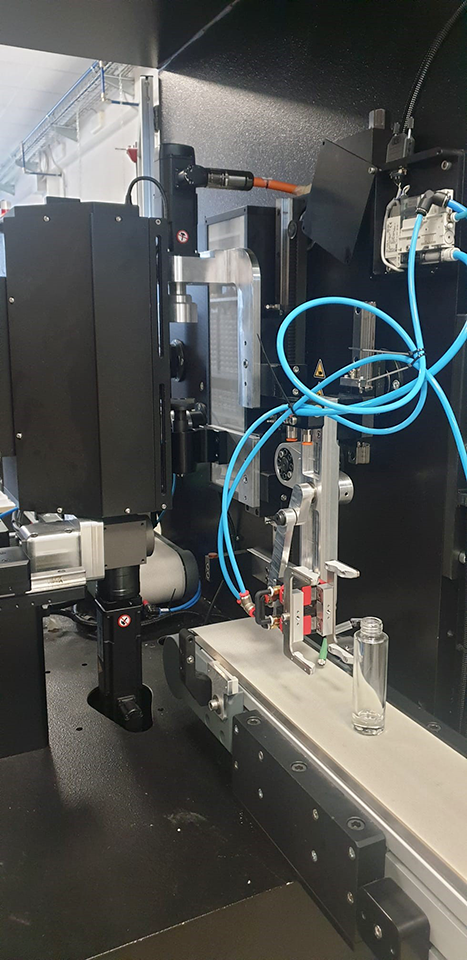

Glass Bottle and Jar Handling For glass bottles or jars, the items are conveyed in a vertical, stand-up position. The pick-and-place system grips each glass bottle or jar and rotates it 180 degrees, positioning the neck downward for inspection. After the control cycle is complete, the bottle or jar is returned to the outfeed conveyor in the same orientation, ensuring smooth and efficient handling.

MULTIPLUS PLASTIC

MULTIPLUS

MULTIPLUS

MULTIPLUS GLASS

Innovation in Print Inspection for Plastic or Glass containers

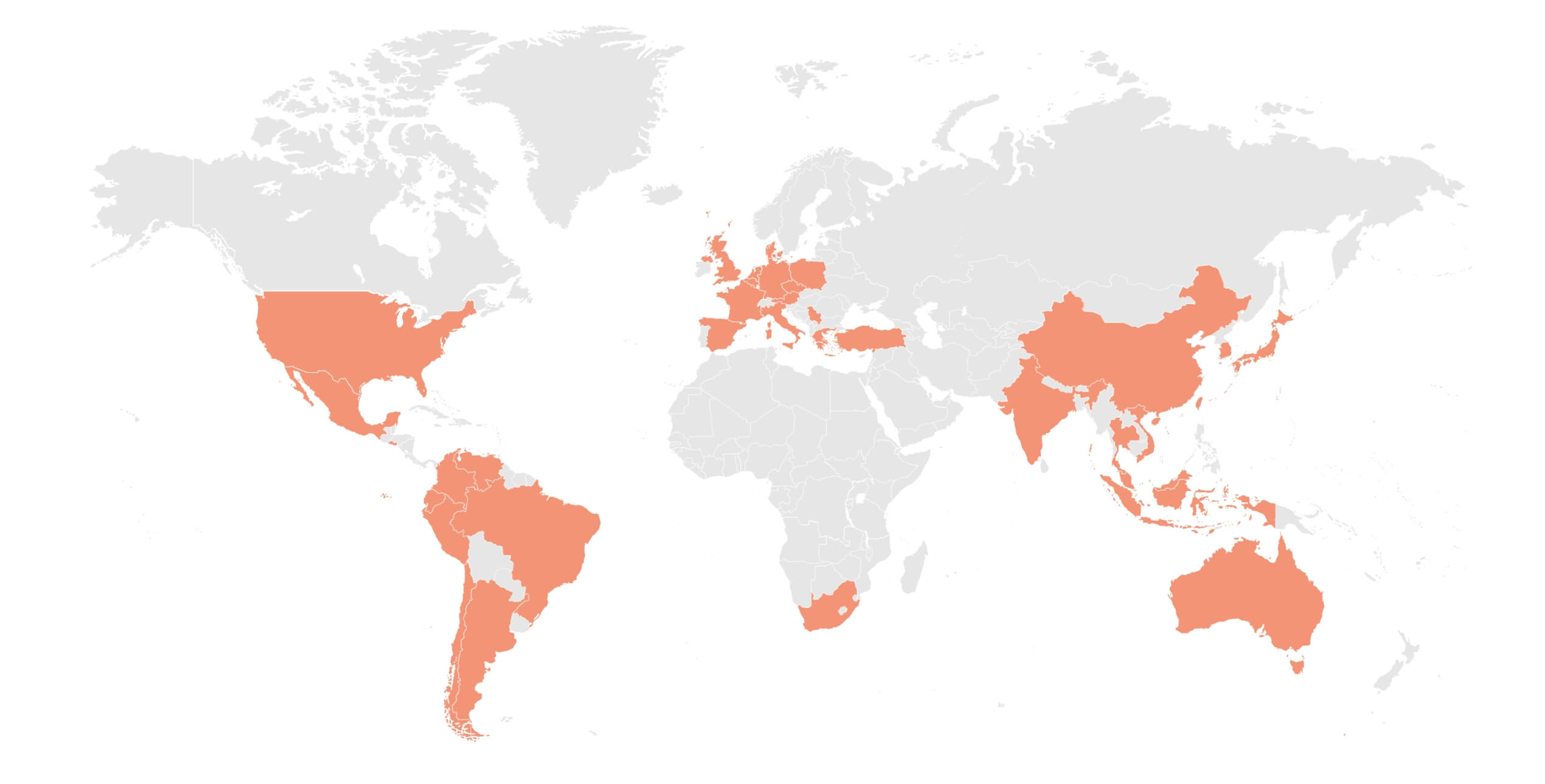

The packaging inspection machine Multiplus guarantees A 100 % quality control module for any type of containers : PLASTIC or GLASS (bottles, mascara, jars, perfume, cosmetic, pharmaceutical,et..)

Multiplus packaging inspection machine: versatility and precision.

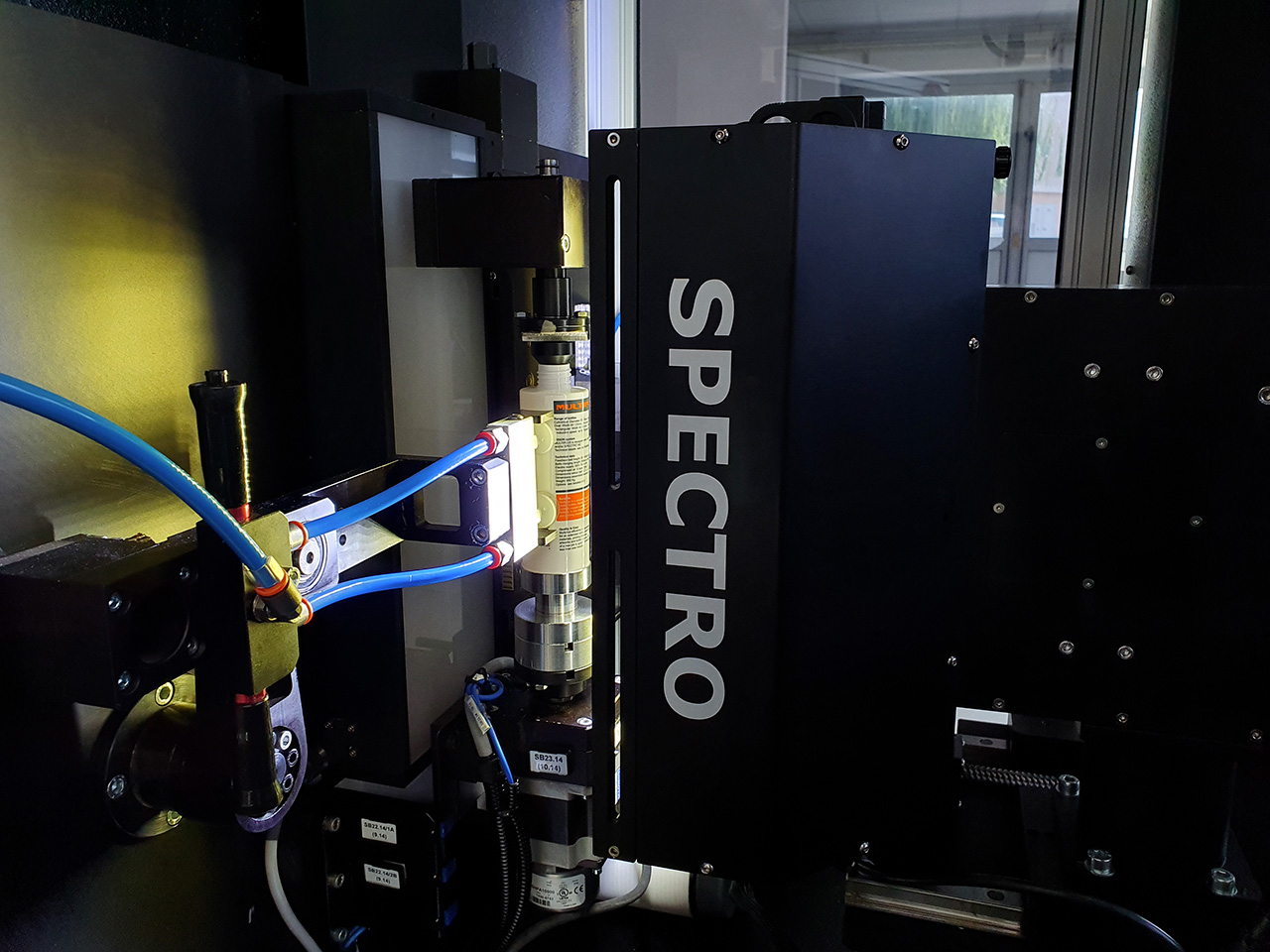

The Print inspection module is designed for the control of plastic and glass containers. Consisting in loading conveyor equipped with pick & place, a between end opening-closing and a servo driven rotation of the item, unloading pick & place onto outfeed conveyor. The defects are rejecting on a specific exit. The module ensures a perfect control up to 70 p/min according to type of bottle.

MULTIPLUS

The advantage of the Print Inspection module MULTIPLUS

Multiplus packaging inspection machine offers numerous benefits, including significant improvement in print quality and reduced waste. Online integration allows defects to be detected and corrected in real time, preventing widespread errors and reducing the amount of waste. This results in reduced costs and increased production efficiency, improving the company’s profitability and reputation.

Reducing waste and thus costs

High accuracy and better efficiency

Ease of use

ASSISTANCE

DeCoSystem guarantees excellent customer service with quick response time and effective solutions. We provide turnkey equipment, great flexibility and software customization, backed by proven experience in the field

+39 055 4564748 | info@decosystem.com