INSPECTOR DECOSYSTEM

Advanced quality control system for surface inspection: web, laminated film, metallization line

SURFACE INSPECTION ON DIFFERENT LINES

The Inspector product line includes two main quality check system: Inspector and Inspector MET. Both models offer advanced surface inspection solutions, but are designed for specific applications, always ensuring the highest quality and reliability.

SPECTRO-M

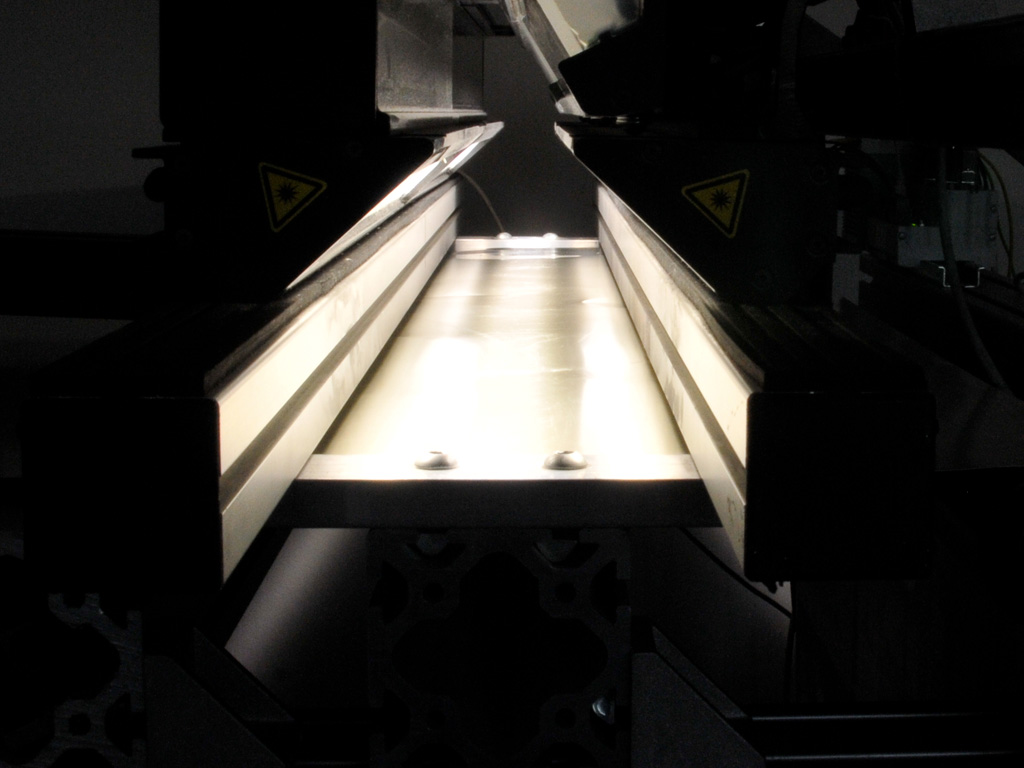

Surface inspection for metallizing machines

Inspector MET is specifically designed for surface inspection in metallizing machines. Its modular configuration allows for quick and easy integration into any production line. You can configure the appropriate network width and lighting for each application, ensuring precise and reliable control. It can also be integrated with an optional module for optical density measurement. This feature allows optical density control over the entire surface, ensuring uniform, defect-free quality.

INSPECTOR-MET

Versatile inspection for various applications

Inspector is designed for a wide range of surface inspection applications. Due to its modular configuration, it can be easily integrated into any production line. You can configure the appropriate network width and lighting for each application, ensuring precise and reliable control. Inspector not only detects and classifies defects, but also helps to improve the production process. When a defect is detected, the operator is notified and the type of defect is recorded, providing a detailed report for each roll inspected. This makes it possible to optimize processes and increase productivity.

INSPECTOR

Inspector, quality check system for surface inspection

The Inspector quality check system offers a highly modular configuration, making it easily integrable into any production line. It can be configured to suit various web widths and illumination types, making it ideal for a broad range of industrial applications.

Precise scanning for each type of surface, example flexible packaging.

Inspector vision systems are designed to inspect a wide range of surfaces, detecting defects such as bubbles, wrinkles, spots and other typical material defects. Thanks to the modular configuration, the appropriate mesh width and lighting can be adapted for each specific application. This ensures accurate and reliable control over the entire surface, improving the overall quality of the product.

THE ADVANTAGES OF THE INSPECTOR SYSTEM

There are many benefits of using Inspector systems, including significant improvement in product quality and increased productivity. When a defect is detected, the operator is immediately notified and the type of defect is recorded to provide a detailed report for each roll inspected. This makes it possible to optimize production processes, reduce waste and increase business profitability.

Reducing waste and thus costs

High accuracy and better efficiency

Ease of use

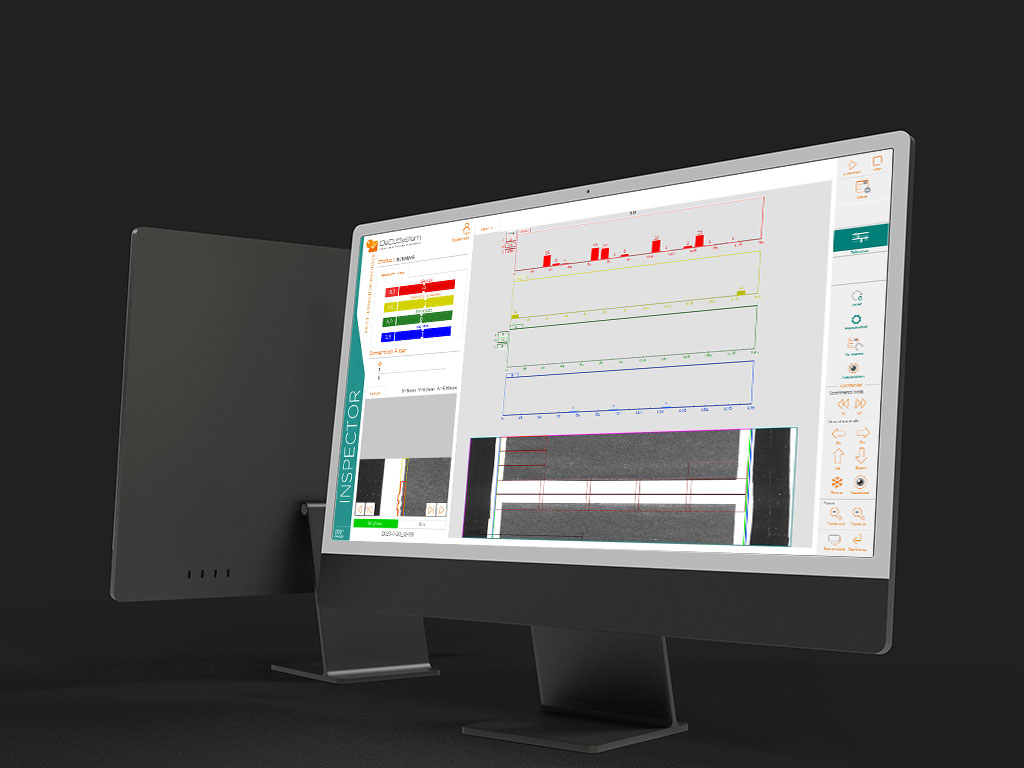

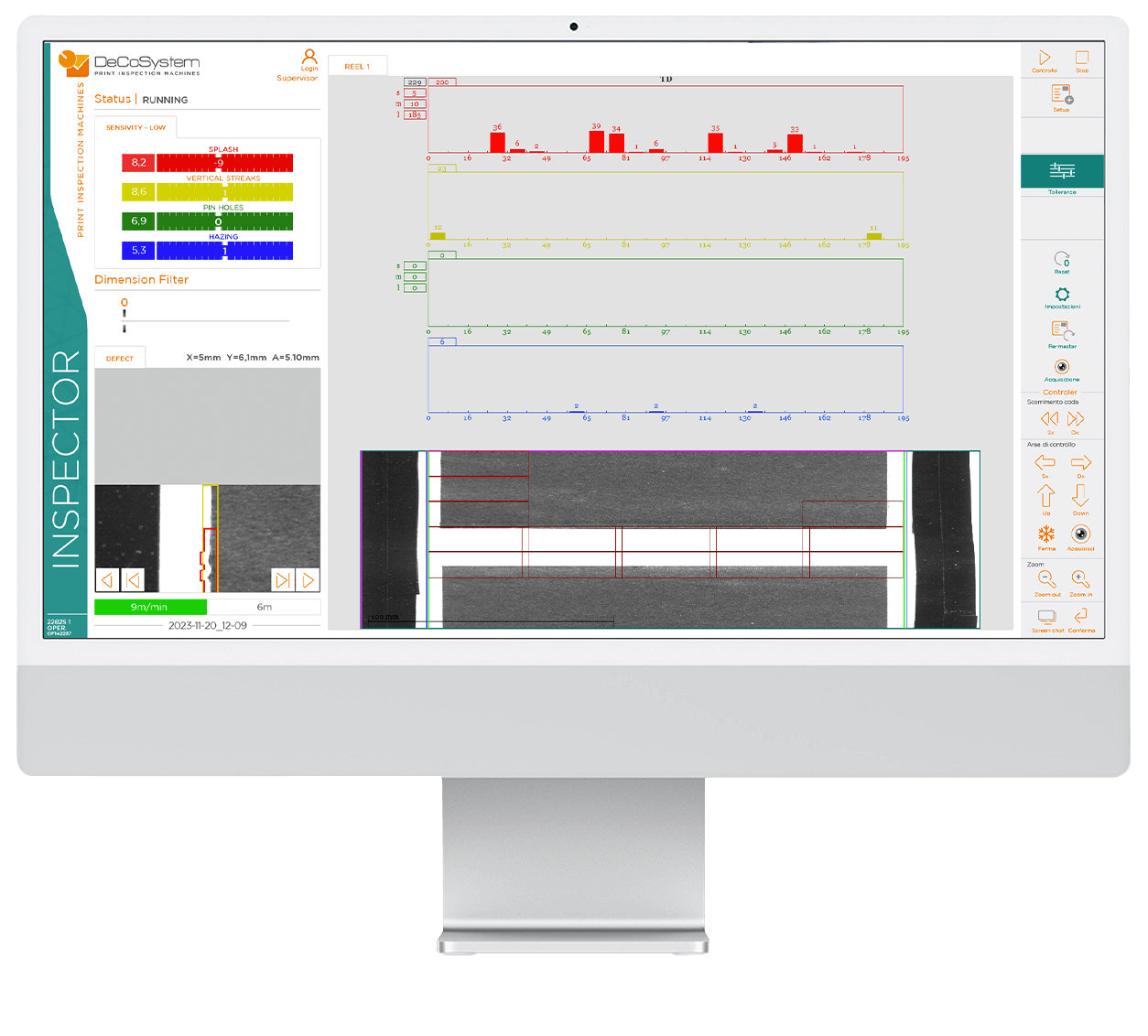

OUR SOFTWARE FOR PRECISION SCANNING

Inspector

Inspector’s software is at the heart of our inspection technology, combining an intuitive interface with powerful defect detection algorithms. Designed to be easy to use, it allows new jobs to be set up in less than a minute and offers a wide range of features, including full reporting and automatic storage of all production process data. This ensures that every detail is monitored and optimized, ensuring excellent print quality at all times..

ASSISTANCE

DeCoSystem guarantees excellent customer service with quick response time and effective solutions. We provide turnkey equipment, great flexibility and software customization, backed by proven experience in the field.

+39 055 4564748 | info@decosystem.com