SPECTRO DECOSYSTEM

Print quality inspection systems for containers: Plastic, Glass and Aluminium.

FOUR SOLUTIONS FOR EVERY CONTROL NEED

The print quality inspection systems Spectro product line includes four main models, each designed to meet specific inspection needs on different materials and shapes. Whether plastic bottles, cylindrical metal objects, glass bottles or flat and oval surfaces, DeCoSystem offers the perfect solution in print quality inspection for every need.

Inspection of plastic bottles and tubes

Spectro-L features a line-scanning camera optimized for inspecting cylindrical objects such as pipes, bottles, containers and plastic caps. It ensures automatic centering of the image of the inspected object with respect to the reference model, ensuring flawless print quality…

SPECTRO-L

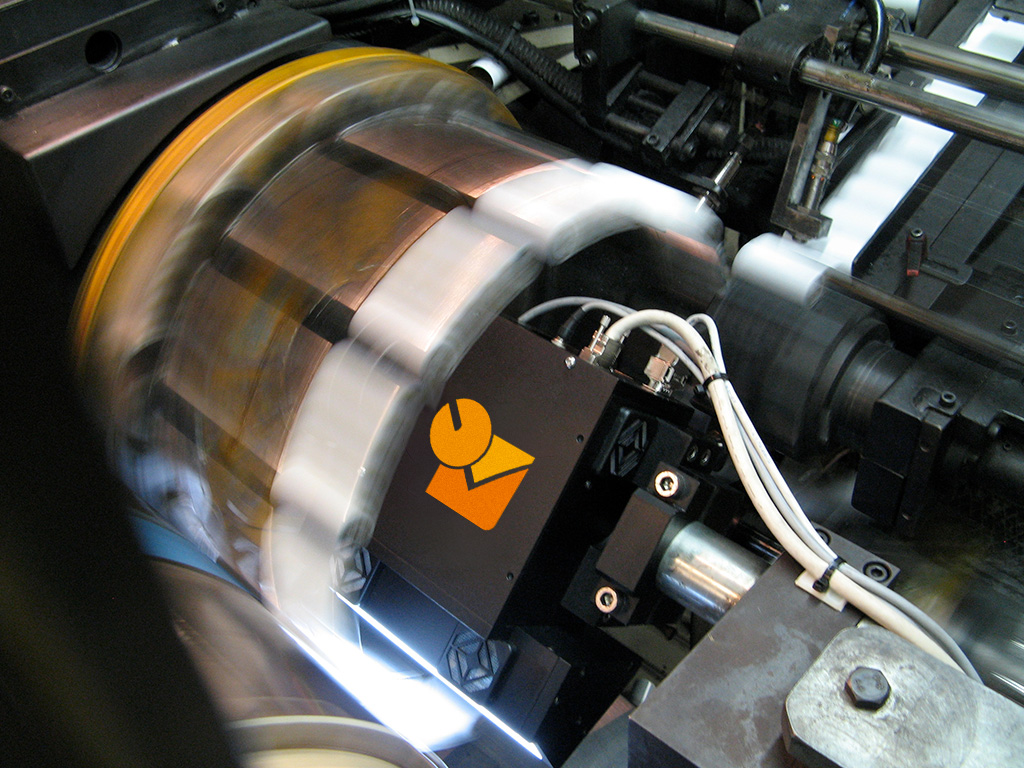

SPECTRO-AL

Inspection on cylindrical metal objects

Spectro-AL is designed to control printing on cylindrical metal objects such as aluminum tubes, caps, cartridges, and aerosol cans. This system ensures high print quality and significant waste reduction through online integration and precise control.

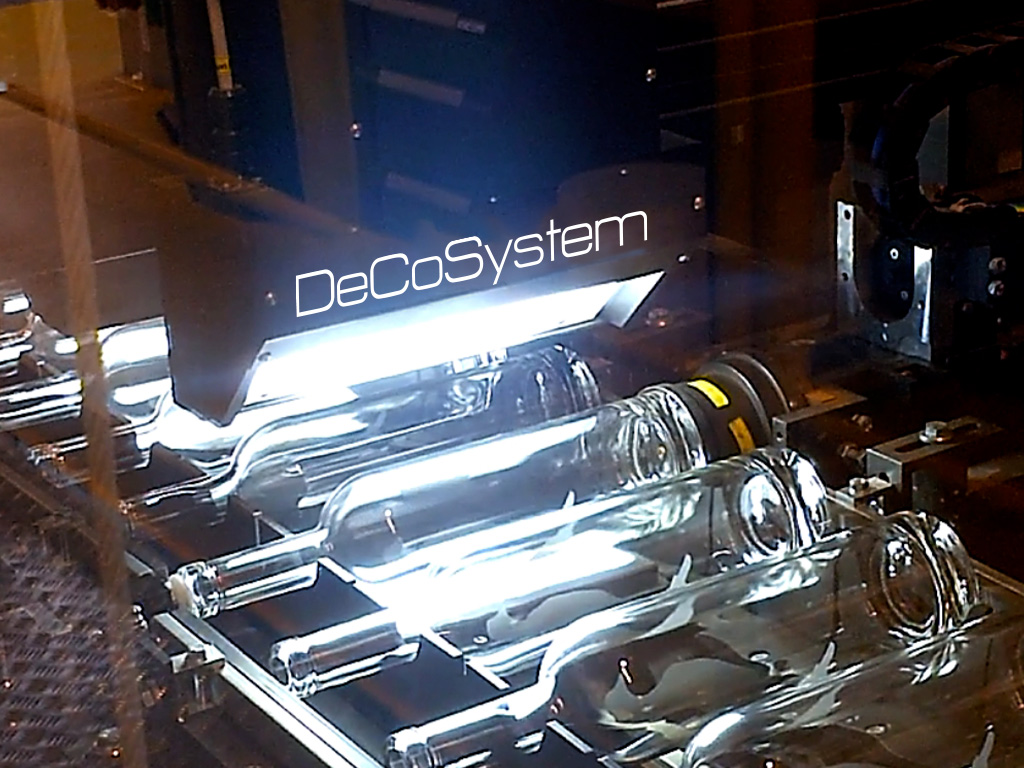

SPECTRO-G

Inspection on glass bottles

Spectro-G is dedicated to the inspection of printing on cylindrical and oval glass objects, such as bottles and tumblers. With the ability to detect major printing problems generated by screen printing and digital processes, Spectro-G ensures defect-free and optimized production.

SPECTRO-M

Inspection on oval and flat objects

Spectro-M is equipped with one or more matrix cameras and is designed to inspect printing on different types of objects, including flat and oval surfaces. This print quality inspection system offers precise control and waste reduction due to its versatile integration and ease of use.

Spectro: print quality inspection system

Print quality inspection systems for Plastic, Glass and Aluminium containers. Our systems can be integrated inside any decorating equipment:

- Screen printing, offset, and hot stamping on plastic or aluminum objects

- Silkscreen printing on glass

- Flexography and gravure for flexible packaging

- Offset for continuous forms and patient information sheets

- Offset for sheets and boards

- Offset and flexo for labels and multifoil material

- Digital printing

Dedicated for any type of containers : tubes, jars, bottles, sticks, pumps, closures, cartridges, mascara, lipstick, pencils, etc….

Perfect Control on Every Surface

Spectro print quality inspection systems are designed to provide accurate and detailed scanning on any type of product, whether plastic, metal, or glass. Thanks to the advanced technology of our cameras and the integration of state-of-the-art image analysis software, we can detect even the smallest defect. This ensures superior print quality and helps prevent problems along the entire production line, minimizing waste and optimizing the production process.

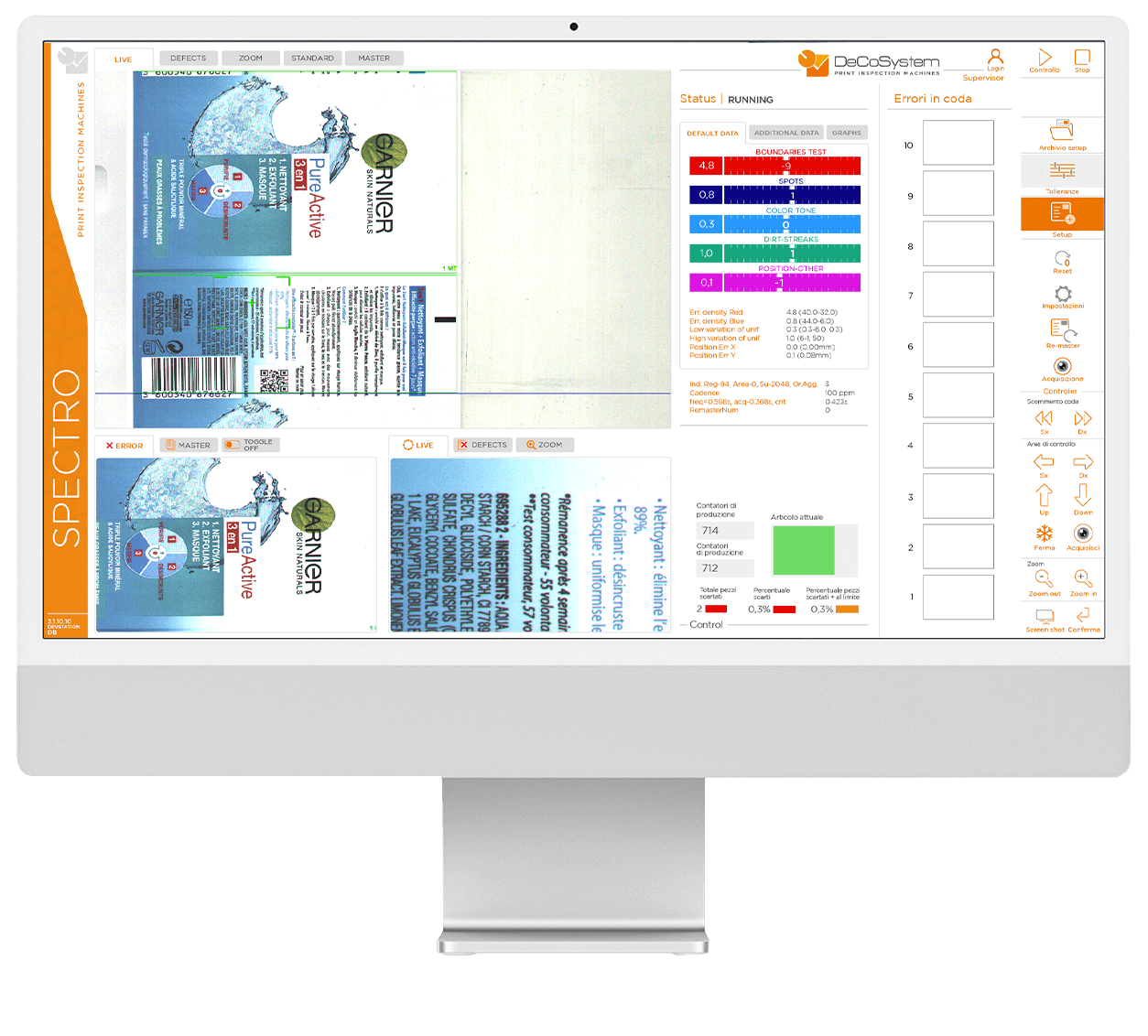

INTUITIVE SOFTWARE AND USER FRIENDLY INTERFACE

Spectro

Spectro’s software is at the heart of our inspection technology, combining an intuitive interface with powerful defect detection algorithms. Designed to be easy to use, it allows new jobs to be set up in less than a minute and offers a wide range of features, including full reporting and automatic storage of all production process data. This ensures that every detail is monitored and optimized, ensuring excellent print quality at all times.

ASSISTANCE

DeCoSystem provides excellent customer service with fast response times and effective solutions. We provide turnkey equipment, great flexibility and software customization, backed by proven experience in the field.

+39 055 4564748 | info@decosystem.com