MINITUB DECOSYSTEM

Tubes inspection machine | Offline module for Print Inspection of plastic tubes

MINITUB, TUBES INSPECTION MACHINE, FEATURES AND TECHNICAL DATA

Tubes inspection machine Minitub is a versatile and powerful inspection machine ideal for quality control of plastic pipes. The machine is equipped with the SPECTRO-L vision system, which ensures 100 percent inspection of the print. It can be used as an independent module or integrated directly into the production line, placing it after the printing press or after the cap machine. With a 5-axis mechanical transport system, Minitub ensures precise and reliable handling of tubes throughout the inspection process.

.

MINITUB

MINITUB print quality and waste reduction.

DeCoSystem’s tubes inspection machine Minitub is an advanced inspection system designed to ensure the highest print quality on plastic tubes while minimizing production waste. With its defect detection capability and control accuracy, Minitub ensures defect-free print production, improving the efficiency and overall quality of the production process.

Excellence in plastic pipe inspection.

Tubes inspection machine Minitub is a versatile and powerful inspection machine ideal for quality control of plastic pipes. The machine is equipped with the SPECTRO-L vision system, which ensures 100 percent inspection of the print. It can be used as an independent module or integrated directly into the production line, placing it after the printing press or after the cap machine. With a 5-axis mechanical transport system, Minitub ensures precise and reliable handling of tubes throughout the inspection process.

MINITUB

Small size

Tubes inspection machine Minitub is designed with compact dimensions to fit easily into any production environment. Robust construction ensures long service life and consistent reliability. Despite its small size, Minitub offers outstanding performance, making it an ideal choice for high-productivity operations.

Increased production

Minitub is designed to increase production because of its ability to inspect pipes at high speed with precision and reliability. Mechanical conveying systems and advanced acquisition units enable high production standards to be maintained, reducing downtime and improving overall operational efficiency.

Detection of defects

The Minitub inspection system can detect minimal defects through the use of high-resolution cameras and advanced lighting systems. This precision ensures that each tube is checked with the utmost accuracy, eliminating defective products and ensuring superior quality.

Online Integration

Tubes inspection machine Minitub offers seamless online integration, allowing real-time control of the production process. This allows any defects to be detected and corrected immediately, optimizing production efficiency and reducing waste. The ability to intervene directly during production ensures consistent quality and a seamless process, improving profitability and corporate reputation

THE ADVANTAGES OF THE MINITUB LINE

Using Minitub offers many benefits, including significant improvement in print quality and reduced waste. The tubes inspection machine ensures reliable defect detection through a combination of advanced printing processes and printed artwork. Quick and easy setup of new jobs in less than five minutes reduces downtime, improving overall efficiency and reducing operating costs.

.

Reducing waste and thus costs

High accuracy and better efficiency

Ease of use

ASSISTANCE

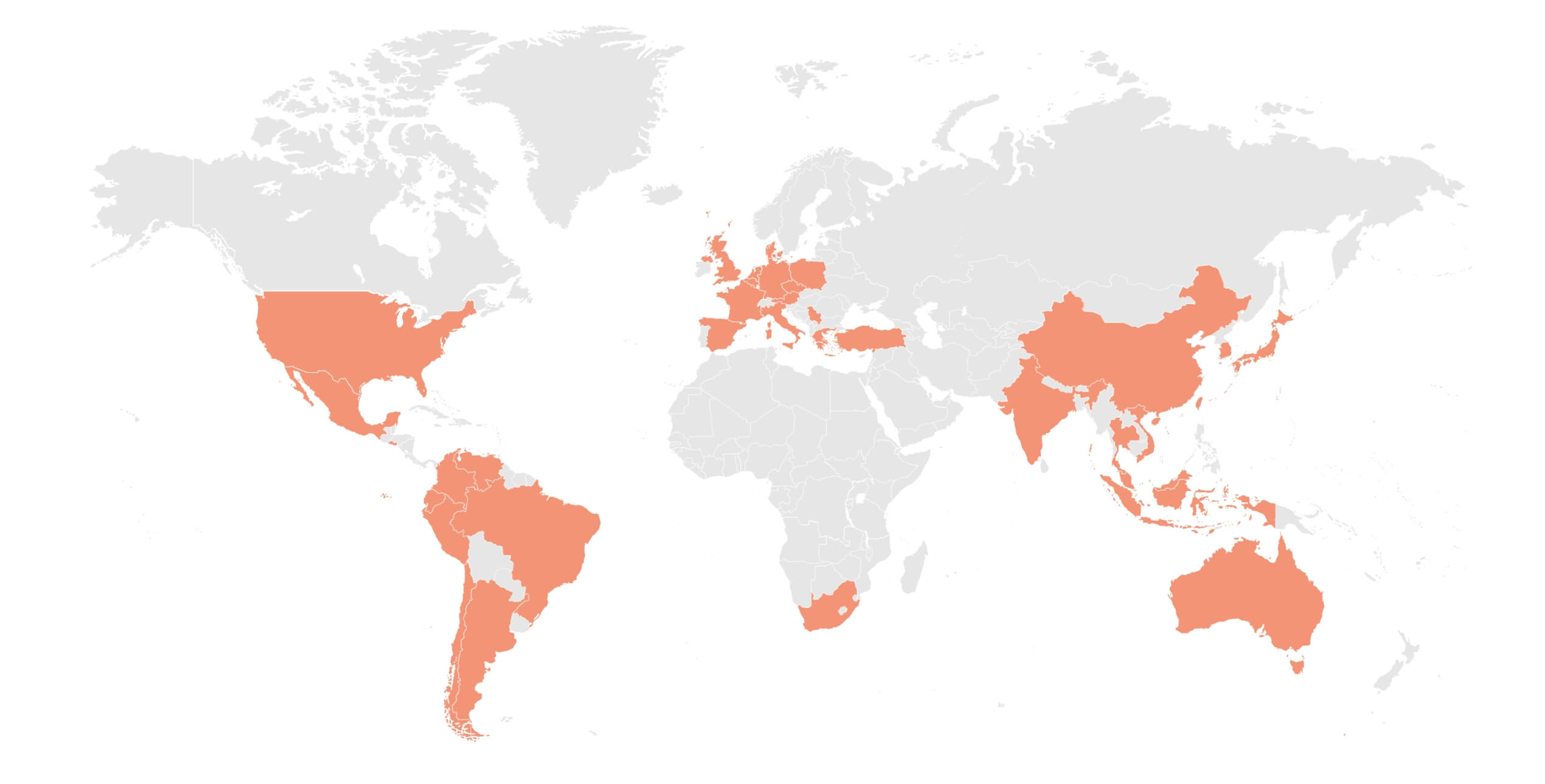

DeCoSystem provides excellent customer service with fast response times and effective solutions. We provide turnkey equipment, great flexibility and software customization, backed by proven experience in the field.

+39 055 4564748 | info@decosystem.com